This "Portable B3" -project

is the main reason why I decided to launch this HammondFinn blog some

time ago. Basicly it's quite traditional Hammond chop, a

try to get full console organ to more transportable form, but it's

also my personal study of Hammond philosophy.

Weight and bulky shape have been main problems over the time Hammond organs have been used in live

performances. Size can be reduced by cutting lower part off, but as

upper compartment still contains all the heavy parts, it's not a real

solution for portability. When it comes to non-musical aspects,

the outlook of real console organ, B3 or C3, is quite often pretty

important. And not the outlook only, but the real feel of solid and

sturdy instrument instead of plastic keyboard on wobbling lightweight

stand.

So my approach to the problem was to

split weight to separate modules and still keep the original look and

feel as far as possible. For this reason I ended up to build

completely new housing so that I got freedom to form parts just as I

wanted.

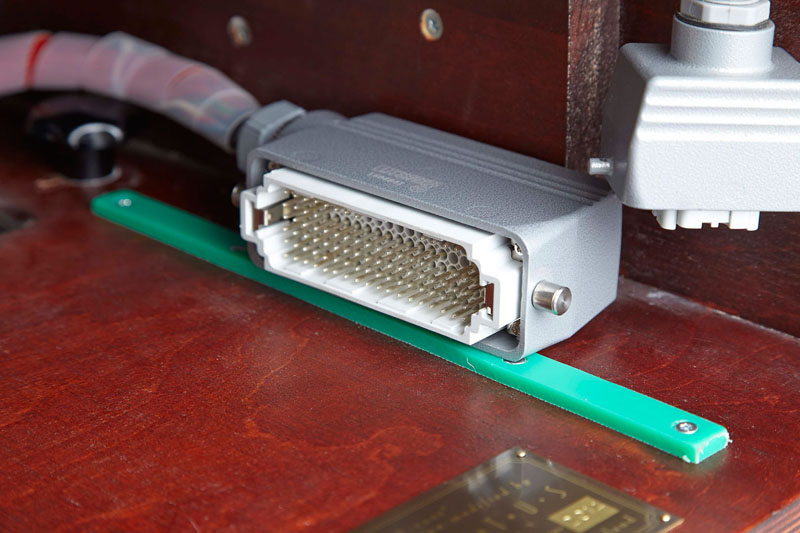

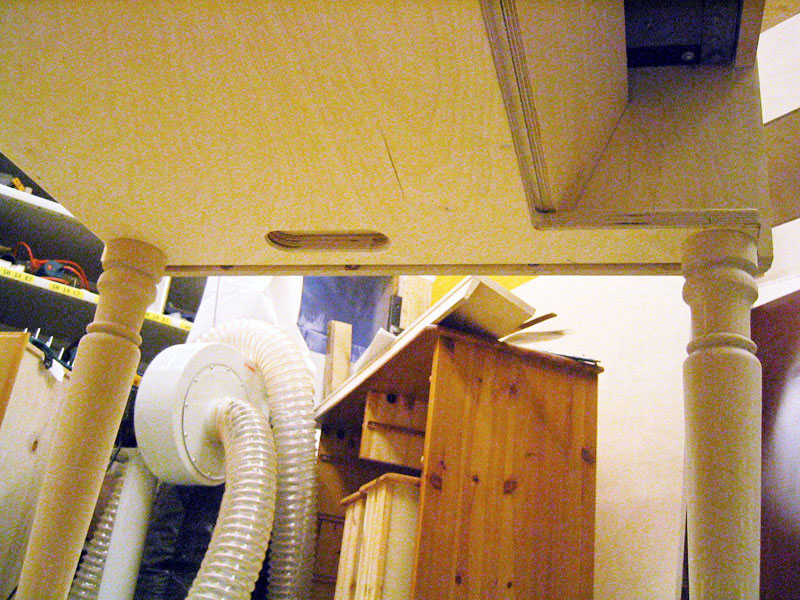

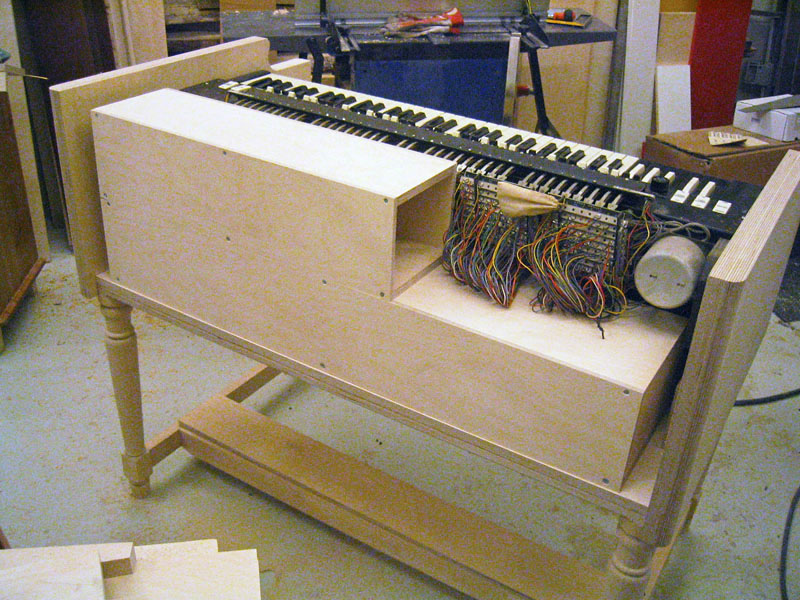

The instrument splits now to six parts; upper compartment with keyboards only, tone generator unit, preamp unit, lower compartment with pedalboard contacts, pedalboard and bench. Electrical units are linked together with industrial grade multipole connectors, so basically there are three connectors to get the organ ready to play or move.

As the project was an unique prototype,

most of plans were in my head and formed out during actual work,

which every now and then made progress really slow. I decided to

use birch plywood for most parts of the housing, as my main target was

to build up robust instrument for gigging musician.

Dimensions of original Hammond parts determined all measurements, so I needed to make certain modifications to get all the components fit in; for instance, preamp power transformer is now mounted beside preamp and expression pedal capacitor housing is turned on its side, both to reduce height of preamp case.

Dimensions of original Hammond parts determined all measurements, so I needed to make certain modifications to get all the components fit in; for instance, preamp power transformer is now mounted beside preamp and expression pedal capacitor housing is turned on its side, both to reduce height of preamp case.

I also wanted to keep the preset panel

because it is one of typical console Hammond features, but as it couldn't be

left on it's original place and position, I had to rebuild panel

frame upside down, rewire it and match it to fit in free space. Switch is for selecting ground lift.

All wooden parts

are stained as cherrywood with slight reddish tint and finished with

2-component satin lacquer. There were several challenges to arrange

proper conditions for air spray painting in workshop at my

photostudio, but after all I was quite satisfied to results.

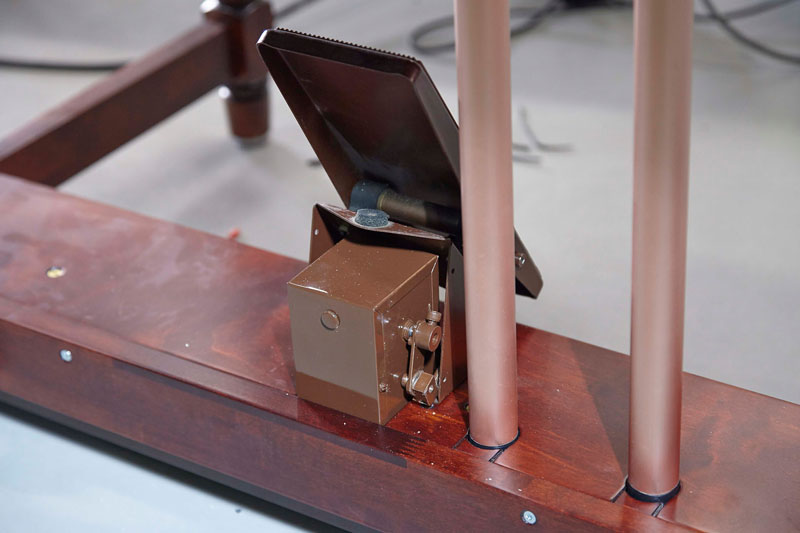

Expression pedal was one of the most

challenging part to solve; originally it has simple mechanic linkage from

pedal to preamp housing, but as all of my units were now detachable

and sealed, it was difficult to easily arrange any mechanical

connections between them. My first try was to move expression capacitor housing

from top of preamp to underneath pedal assembly and connect them

together with shielded cable to avoid hum and noise on this high

impedance part of circuit. It worked, but volume response had a nasty

delay, obviously caused by increased length of wiring.

I finally built expression control with

a servo motor; the controller located on preamp housing reads value

from potentiometer which is linked with expression pedal and then

servo mechanically moves original control shaft.

Another challenge related to high

impedance amplifier circuits was wiring from vibrato scanner to

preamp terminal "D". Although shielded, it is extremely

sensitive to any interference and easily causes noise and hum,

especially if the length of wiring is increased. After trying

different types of shieldings and grounding points with results of

different type buzzing and humming, I finally took separate short

coaxial line with BNC connectors from generator unit to preamp unit

and got rid of any noises. Other tone generator wirings remained quite close to their original length, so I didn't find problems with them.

During years I have made several leslie

modifications for solid state speed switching relays, so it was

natural add-on here too. This organ was meant to be used with leslie

122, therefore I modified connection so that instead of practically

useless B+ feed on pin 5, it is now used to send low level control

voltage to solid state relays in the leslie amp. By this means I got rid

of switching delays of original phantom voltage mixed in audio signal

and also getting full slow-off-fast control by simple voltage

polarity switching.

Same modification is even more

functional with unbalanced type leslies (147, 145, 251... etc) as they

originally use mains AC voltage to control original relay. In these

systems switching sparks often cause electrical noises, but what I

personally feel the most uncomfortable image, is having a lethal voltage

inside fragile bakelite leslie switch body just underneath my fingers. The very

same switch is mainly used as electric guitar pickup selector, so it's

really not a perfect item to make any high voltage connections.

Naturally, the switch unit is meant to be easily detachable with two thumbscrews and robust XLR-connector.

Naturally, the switch unit is meant to be easily detachable with two thumbscrews and robust XLR-connector.

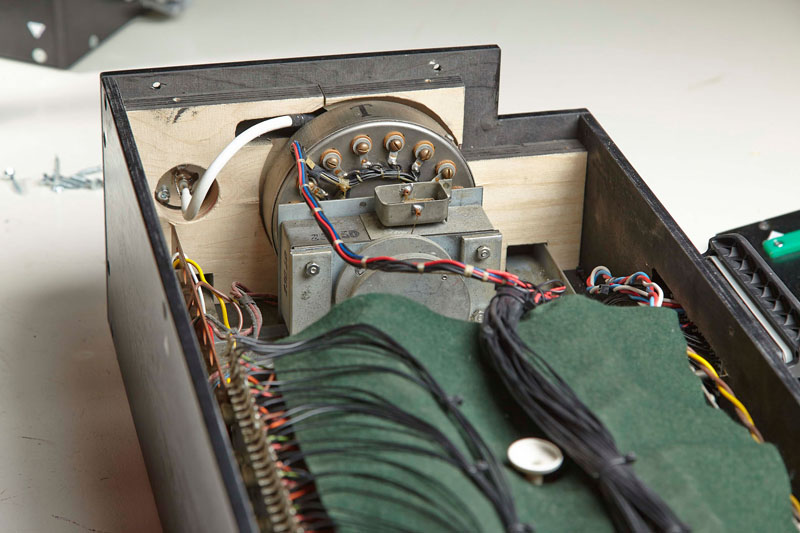

As the organ was almost completely

parted during the project, I also made normal service operations like

busbar cleaning. I renewed electrolytic capacitors from organ and

leslie amplifiers too, as they are aging components anyway. Original

organ used in this project was Hammond A100 from early 70's, so it

had newer red mylar filter caps in generator and after all those

service procedures overall tone was really bright, punchy and powerful. Most

probably it was what all Hammonds have been when they rolled out from

factory line, but in this case it was a kind of problem, because the new

owner wanted it sound like mid 50's mellow jazz organ...

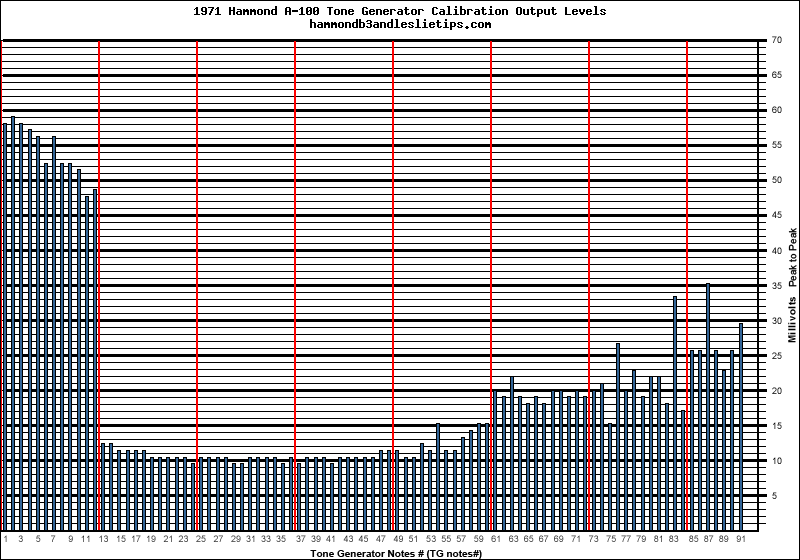

Solution for this was recalibration of

tone generator output voltages. There are available lot of

measurement data of organs from different era, so I first measured

actual voltages to make a chart to compare with all previous

data charts. It showed up that the bright high end curve was similar to

other late model organs (upper image), so I dropped higher tones down and raised

first two octaves a bit to get it closer to older models (lower image). Module

design of my project was now working like a dream, as I just lifted

generator unit on bench, unscrewed lids to expose pickups from both

sides and then temporarily connected mains to start and run motors.

So, what are my conclusions after all efforts?

Using term "portable" is maybe too extravagant in case of

any old tonewheel Hammond, as the heaviest unit of the organ is still

pretty heavy, although it won't break up your back so easily.

Actually, the total weight is now even higher than original B3 due to

extra housings, but on the other hand it is possible to divide to

lighter components which was my original idea. The best solution in

any case is use some kind of wheel dollies whenever it is possible,

so the final stage to my project was making roll-or-kari -type simple

wheel dollies from lightweight aluminium profile.

Without generator and preamp units the organ is now noticeable easier to lift and handle on dollies. And in my humble personal opinion, it's a real beauty compared to any Hammond chops I have seen so far.

Without generator and preamp units the organ is now noticeable easier to lift and handle on dollies. And in my humble personal opinion, it's a real beauty compared to any Hammond chops I have seen so far.